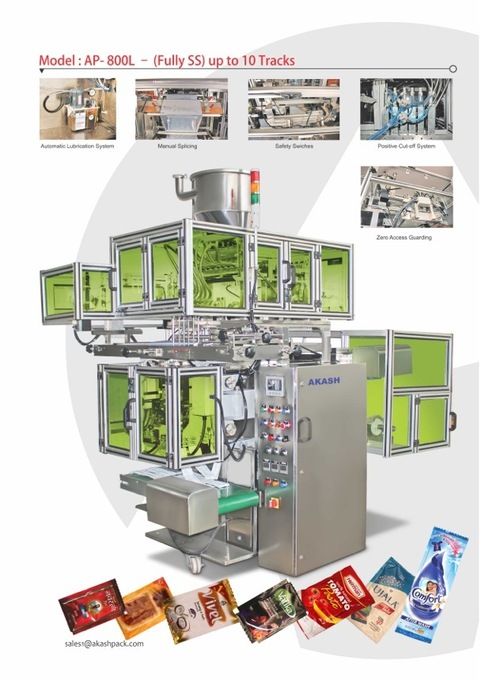

Welcome To Akash Pack Tech PVT. LTD.

Automatic Multi Track Pouch Packing Machine

Product Details:

- Material SS

- Feature Highly Efficient Heavy Duty Machine

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Drive Type Electric

- Color White

- Click to View more

X

Automatic Multi Track Pouch Packing Machine Price And Quantity

- 1 Unit

Automatic Multi Track Pouch Packing Machine Product Specifications

- No

- 1 Year

- White

- Human Machine Interface

- Highly Efficient Heavy Duty Machine

- Electric

- Automatic

- SS

Automatic Multi Track Pouch Packing Machine Trade Information

- 30 Unit Per Month

- 8 Week

- All India

Product Description

An Automatic Multi-Track Pouch Packing Machine is a type of packaging machinery designed to automatically fill and seal multiple pouches simultaneously. These machines are commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and others where products are packaged in pouches.

Here are some key features and aspects of an Automatic Multi-Track Pouch Packing Machine:

1. Multi-Track Capability: The term "multi-track" indicates that the machine has multiple lanes or tracks, allowing it to work on several pouches concurrently. This increases the overall packaging speed and efficiency.

2. Automatic Operation: These machines are designed for high-speed and automatic operation. They can perform tasks such as pouch filling, sealing, and sometimes additional functions like printing batch numbers or date coding.

3. Versatility: These machines are versatile and can handle a variety of pouch types, sizes, and materials, including stand-up pouches, flat pouches, and more. This versatility is crucial for businesses that need to package different products.

4. Precision and Accuracy: The machines are engineered to deliver precise and accurate filling to ensure consistency in product weight or volume in each pouch.

5. Integrated Controls: Advanced machines often come with user-friendly control interfaces that allow operators to set parameters, monitor the packaging process, and make adjustments as needed.

6. Sealing Mechanism: Depending on the machine's design, the sealing mechanism can vary. Common sealing methods include heat sealing, ultrasonic sealing, or other advanced techniques suitable for the specific packaging material.

7. Packaging Materials: These machines can handle a range of packaging materials, including various types of films, laminates, and foils.

8. Easy Maintenance: To minimize downtime, these machines are often designed for easy cleaning and maintenance, with accessible components for routine checks and repairs.

9. Customization Options: Some machines may offer customization options to adapt to specific packaging requirements, such as adding features for zip-lock sealing, spouts, or other special pouch features.

10. Compliance: In industries like pharmaceuticals or food, these machines need to adhere to strict regulatory standards, and manufacturers often design them with compliance in mind.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free