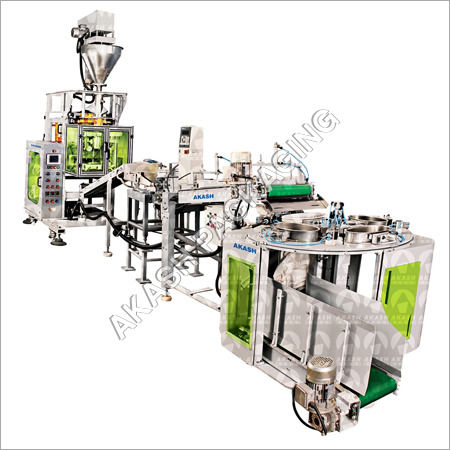

Double Track Auger Filling Machine

Product Details:

- Material SS

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Drive Type Electric

- Voltage 4 Watt (w)

- Weight (kg) 1200 Kilograms (kg)

- Click to View more

Double Track Auger Filling Machine Price And Quantity

- 1 Unit

Double Track Auger Filling Machine Product Specifications

- 4 Watt (w)

- Human Machine Interface

- Automatic

- Electric

- 1 Year

- 1200 Kilograms (kg)

- No

- White

- SS

- 1000 X 500 x 1800 Millimeter (mm)

Double Track Auger Filling Machine Trade Information

- 30 Unit Per Month

- 8 Week

Product Description

With the vast experience in the industry, our team of professionals has enabled us in the manufacturing and supplying high quality Double Track Auger Filling Machine. In the manufacturing process, we use high-grade quality raw material to meet the industry trends. These products are well known for their excellent performance, low maintenance and robust construction. Our customers can avail these products at reasonable prices from us. Double Track Auger Filling Machine is highly appreciated by our customers for its smooth functioning and easy operation.

AP 220P Augur Filler Machines

Model: AP- Collar- 220P Auger (UP TO 2 Tracks)

Salient Features

The range of Model AP-Collar- 220P Auger Filler Single Lane/Double Lane pouch filling machines are available in various web control options such as electronic web edge control and pneumo hydraulic web edge controller. These machines are mainly used for the pouch filling of free flow powder, non free flow powder and granules products. The speed of this model of VFFS pouch filling machines can go up to 80 SPM depending on the pouch dimension. These are available in servo and clutch brake film draw mechanism & are offered an industry leading prices. We use premium grade raw material and advanced technology to manufacture these machines.

Best Suitable For :- Powder Hair Dye; Heena ; Spices; Milk Powder ; Etc.

Technical Specifications :-

|

Machine Speed |

Up to 80 SPM depending on the product and sachet/pouch dimension. |

|

Packing Range |

Suitable to pack up to 50 gram and above depending upon product to be packed |

|

No. of Tracks |

Single Track |

|

Max. Roll Width |

250 mm |

|

Max. Roll Dia |

180 mm |

|

Max length of pouch |

Up to 140 mm |

|

Film Draw Mechanism |

Options : (A) Servo (B) Clutch and Brake mechanism |

|

Web Controller |

Options : (A) Electronic web edge control B Pneumo hydraulic web edge controller |

|

Compressed Air |

6 CFM @ 6 kg/cm sq |

|

Electrical power required |

Up to 4 KW |

|

Main Body Frame |

Options: (A) SS Body (B) MS with Powder coating (C) MS with SS cladding |

|

Type of Sealing |

Option: (A) 4 Side Sealing (B) 3 side sealing (C) Center sealing |

|

Machine Dimension |

1000mm X 500mm x 1800mm(Lmm X Wmm X Hmm) approx |

|

Net weight |

1200 kg |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free