Welcome To Akash Pack Tech PVT. LTD.

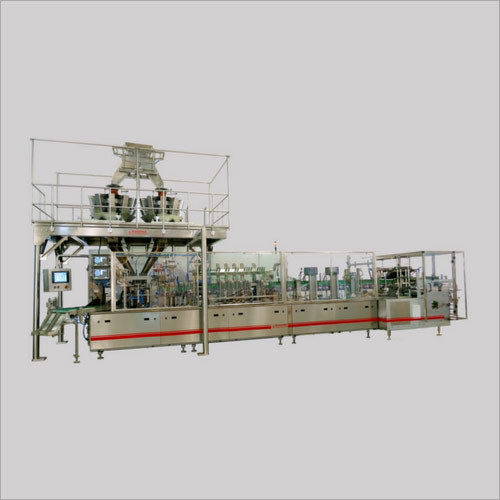

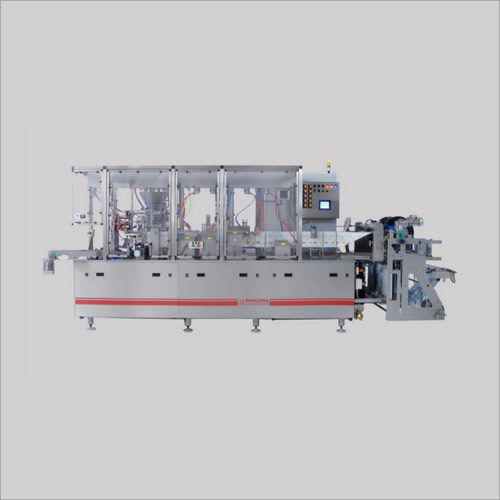

Horizontal Automatic Form Fill Seal Machines

Product Details:

X

Product Description

Horizontal Automatic Form Fill Seal (HFFS) machines are packaging machines that are used to form, fill, and seal flexible pouches or bags horizontally. These machines are widely used in the packaging industry for various products such as snacks, liquids, powders, and granular materials.

Here's an overview of the key features and functions of Horizontal Automatic Form Fill Seal Machines:

1. Forming:

The machine starts by forming a pouch or bag from a flat roll of flexible packaging material, typically made of materials like plastic, paper, or a combination of both.

2. Filling:

After forming the pouch, the machine fills it with the product. The filling process can be designed for different types of products, including liquids, powders, granules, or solid items.

3. Sealing:

Once the pouch is filled, the machine seals it to ensure the product is contained securely. The sealing process may involve heat sealing, ultrasonic sealing, or other sealing methods depending on the material used for the pouch.

4. Cutting:

After sealing, the machine cuts the pouch from the roll, separating it from the continuous material.

5. Advantages:

a. Efficiency: HFFS machines are known for their high-speed operation and efficiency in packaging large quantities of products.

b. Versatility: These machines can handle a wide range of products and packaging materials.

c. Space Saving: The horizontal design allows for a more compact footprint compared to vertical form-fill-seal machines.

6. Applications:

a. Food Industry: Used for packaging snacks, candies, coffee, and other food products.

b. Pharmaceuticals: Suitable for packaging tablets, capsules, and other pharmaceutical products.

c. Cosmetics: Used for packaging creams, lotions, and other cosmetic products.

d. Industrial Products: Applied in the packaging of hardware, fasteners, and other industrial goods.

7. Customization Options:

HFFS machines come in various configurations to meet specific packaging requirements. They may include features such as multi-lane packaging, gas flushing (to extend product shelf life), and printing capabilities for adding product information and branding.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free